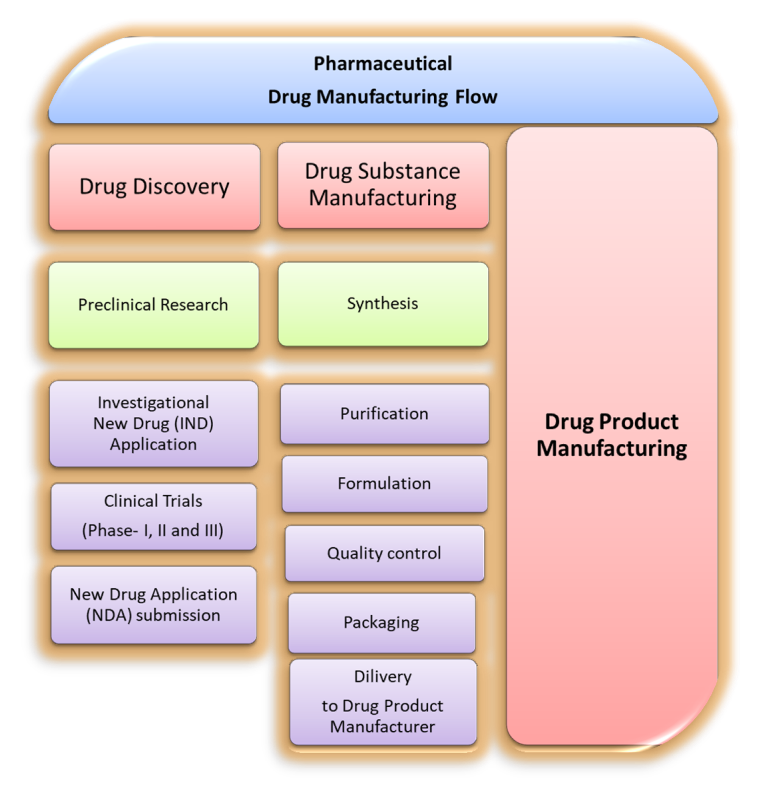

In the world of pharmaceuticals, the drug substance manufacturing process

is a critical component in bringing life-saving medicines to patients. This

complex process involves several steps, adherence to stringent rules, and

upholding the highest standards of quality.

This process is based on the basic

Good Manufacturing Practice (GMP) principles i.e. SISPQ; which means a drug

substance / drug product should be manufactured in such a way, that achieve Safety,

Identity, Strength, Purity and Quality.

In this article, we will go through with the various

phases from drug development through the ultimate delivery of the active pharmaceutical ingredient (API), taking a close look at the manufacturing process of drug

substances/ drug product.

|

| Figure: 01: Pharmaceutical Drug Substance Manufacturing Flow: From Discovery to Delivery |

1. Drug Discovery

The process of producing drug substances starts

with drug discovery, in which pharmaceutical companies look into and find

prospective new chemicals entity (NCE) that might be used to treat particular medical

conditions.

To find the most promising options with the needed therapeutic

effects, scientists carefully examine thousands of chemicals. An identified

lead compound is put through extensive testing to determine its safety and

effectiveness.

|

| Figure: 02: Drug Discovery |

2. Preclinical Research

As a result of drug discovery, once the lead compound

is identified, preclinical research starts. This stage involves a deep dive

study performed on cell-cultures and animal models to evaluate the compound’s

pharmacological characteristics, toxicity, and potential side effects.

The

objective of this stage is to collect the crucial data and vital information to

assist the “Investigational New Drug (IND)” submission process to

regulatory authorities.

|

| Figure: 03: Preclinical Study |

3. Investigational New Drug (IND) Application

Once preclinical research establishes the safety

and efficacy of the drug candidate, the pharmaceutical company files an IND

application with the regulatory agencies.

This submission includes all relevant

preclinical data, proposed clinical trial protocols, and information on the drug

substance’s manufacturing process.

|

| Figure: 04: Investigational New Drug (IND) Application |

4. Clinical Trials

Clinical trials are a set of carefully organized

experiments carried out on healthy people in order to evaluate the efficacy,

dose, and safety of the drug substance. These studies are conducted under

stringent restrictions & guidance.

This stage typically has four phases.

Phase I: focuses on establishing safety and dose,

Phase II: assesses efficacy

and further safety, and

Phase III: entails large-scale trials to validate

efficacy and track negative reactions.

Phase IV: Post-Market Surveillance

|

| Figure: 05: Clinical Trial |

5. New Drug Application (NDA)

As the clinical trial study gets completed,

pharmaceutical companies put all the information collectively into a “New

Drug Application (NDA)”.

These information are obtained throughout the

aforementioned earlier stages of drug substance manufacturing. This thorough

dossier contains details on the creation of medicinal substances, including

information on preclinical research and clinical trial findings.

The regulatory

agencies are subsequently given the NDA to evaluate and approve.

|

| Figure: 06: New Drug Application (NDA) |

6. Drug Substance Manufacturing

After receipt of regulatory approval, drug

substance manufacturing gets begins. The process involves multiple intricate

steps, including:

A Synthesis:

The drug’s API is synthesized in controlled laboratory environment /

conditions. The synthesis process must be consistent and reproducible, should

be documented properly to ensure consistent quality as per required acceptance

criteria.

B. Purification: The synthesized API is

purified to remove impurities and unwanted by-products. High-performance liquid

chromatography (HPLC) and other analytical techniques are employed to check and

monitor the purification step, to achieve the desired purity levels.

C. Formulation: Further the Active

Pharmaceutical ingredient (API) undergoes some additional processing steps to

get the final drug product, such as tableting, encapsulation, or suspension in

a liquid form.

D. Quality Control: Throughout the

manufacturing process, rigorous quality control checks are performed to ensure

the quality of API, which meets all required / desired quality specifications.

Any deviations are meticulously addressed to maintain product integrity.

E. Packaging: The final drug substance

(API) is carefully packaged and labeled, now at this stage it is ready for

distribution to various drug product manufacturers.

|

| Figure: 07: Drug Substance Manufacturing |

7. Drug Product Manufacturing

Now, drug substance (API) supplied to drug

product manufacturer for formulating as final drug product. Formulation unit of

drug product manufacturer formulates the APIs into the final dosage forms, such

as tablets, capsules, or injectables.

The process of drug product manufacturing

process follows stringent quality standards & GMP (Good Manufacturing

Practices) guidelines.

|

| Figure: 08: Drug Product Manufacturing |

8. Quality Assurance and Regulatory Compliance

Throughout the entire drug substance

manufacturing flow, quality assurance plays a vital role. Stringent quality

checks are conducted at every stage to comply with various regulatory requirements.

This ensures that the final product is safe, effective, and of

the highest quality.

|

| Figure: 09: Quality Assurance and Regulatory Compliance |

The drug substance manufacturing flow is an

intricate and highly regulated process that plays a crucial role in bringing

life-saving medicines to patients worldwide.

From the early stages of drug

discovery to the final delivery of the API, each step demands precision,

compliance with strict regulations, and an unwavering commitment to quality.

Learn more……..

Pharmaceutical Drug substance (API) and Drug Product: Definition

Product Lifecycle management- An overview

Process Validation study- Types of validation and advantage

Pharmaceutical Purified water system : Fundamental Introduction

Computer system validation (CSV) in Pharmaceutical Industry !! Introduction