Validation

Study: Basic overview

This

Article is written here to have an overview on the validation Study, now a

day’s validation became an integrated part of cGMP. As we all know that the

pharmaceutical industries are manufacturing the life saving drugs, hence the

key objective set by the pharmaceutical industry is to manufacture products of

required attributes and quality with consistency, at the lowest conceivable

cost.

Validation study is the first requirement of any regulatory authority to

give approval of commercialization / Market authorization. Various regulatory

authorities defined the guidance on the Validation study and its approach for execution;

here in this article we are going to have an overview on complete validation

study.

Inside Story

- What

is validation study? - History

of Validation. - Scope

(Phases) of validation.

What is Validation study?

term VALIDATION is self explanatory i.e. “This is a process to prove VALID in

terms of consistency of a particular operation/process”. This is an assessment

process for validity / effectiveness of series of operations. Documented

evidence is being generated throughout the study program, with the reference of

guidance documents of various Pharmaceutical regulatory authorities all over the world.

principal goal of Pharmaceutical Manufacturer is to manufacture product with

the desired /requisite quality. Operational / Mechanical consistency plays a

major role to achieve the prime goal of pharmaceutical manufacturing. This

Operational / Mechanical consistency need to be proved. Validation study also

involves some extra cost to the manufacturing, as this is an extensive study

program to prove the consistency / effectiveness of an operation/process.

prove control on quality of manufactured product, it is very essential to

perform validation study. A process that is well understood and in the state of

confidence, control of product quality of the product manufactured cannot be assured

without validation program.

History

of validation study

Concept

of validation is primarily derived from US FDA (Food and drug association)

regulations describing the current good manufacturing practice (cGMP) for finished

pharmaceuticals (21 CFR parts 210 and 211).

USFDA was the pioneer to advocating

the concept of validation. In the mid of 1970’s this concept was proposed by

two FDA officials names Ted Byers and Bud Loftus. This concept was introduced

looking at the several problems in the sterility of large volume parental

Market. First draft guidance on General principles of Process validation was come

in May 1987.

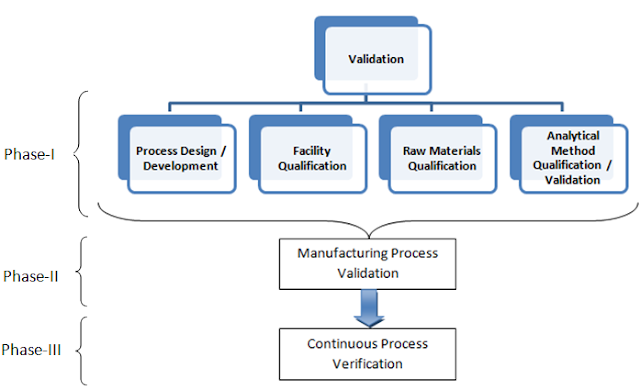

As we

defined, in the above section the term validation is the process to prove operational

and mechanical consistency, scope of validation study program is very vast, it

covers every aspect of the pharmaceutical industry from its establishment to

commercialization of product. An organized overview on validation study scope

defined here, which involves three phases of validation;

- Phase-I: Pre-validation

/ Qualification Phase (Prerequisites of Process validation) - Phase-II:

Validation Execution Phase (Process Validation) - Phase-III:

Validation Maintenance Phase (Continuous process verification)

- Process

Design / Development: This Study is comprise of various Process Understanding

Studies which includes; Process control study, Hold time study, In-process

control study, Filtration study, Drying

Study, Shipping validation, Process Data Trending etc.

- Facility

Qualification: This study is comprised of the study on various parts of a manufacturing

facility which allows manufacturing of product within; likewise Utility

Qualification, Equipment Qualification and calibration study program, Equipment

Cleaning Validation, Operator Qualification etc.

- Raw

Materials Qualification: Raw material Qualification study comprises of Raw

material Analysis, Vendor/supplier Qualification and Transportation validation

study etc.

- Analytical

Method Qualification / Validation: Analytical Method Qualification study involves

the qualification study for the analytical methods Residuals Assay

Qualification, In-process Method Validation, Release Method Validation etc.

Phase-II:

Validation Execution Phase (Process Validation)

In

the first phase of validation i.e. Pre-validation / Qualification Phase we have

understood the things need to be established prior to validate a manufacturing

process of a drug substance (API) / Drug Product. This study is designed to validate or

authenticate that an established sequence of process, established acceptance

criteria and critical / non critical process parameters are suitable and

adequate.

This study is a type of declaration that particular process can

produce with the consistency operation / procedural and quality point of view over

the period of time even under the worst conditions.

Phase-III:

Validation Maintenance Phase (Continuous process verification)

This

is the maintenance phase of manufacturing process of drug substance (API) /

Drug Product.

As the name suggest it requires a frequent review of all process/product

related documents which involves Manufacturing process, Quality management

system (QMS) documents, analytical documents etc. Intention for the review of

all this documents is to ensure that it have been no changes have been made /

occurred in the process after execution of Phase-II i.e. process validation

study, No Failure, deviations and modification took place without any

investigation or acknowledgement.

Team comprising of representatives of major departments ensures that there is

no impact on the existing validation study performed in the Phase-II. No such deviation/failure

occurred that impacted the validation study and ought to recommend performing

re-qualification re-validation study.

This maintenance study could be an alert system

design and validation of the system that shows high degree of assurance that

all the lots and batches manufacture will achieve their particular established

specifications.

I

hope this article on basic introductory knowledge on validation study in pharmaceutical industry, helps you to boost up your knowledge stock of your mind.

Other useful

articles may informative…..

- Product

Lifecycle Management: An Overview - Pharmaceutical

regulatory authorities All over the world - Pharmaceutical

Quality Management System: An overview - What

is Quality Management system for pharmaceutical industry? - Elements

of Quality management system: An overview - Pharmaceutical

Drug substance (API) and Drug Product: Definition - Research

and Development: Definition

Very informative and nicely presented.

Thank you sir….!!