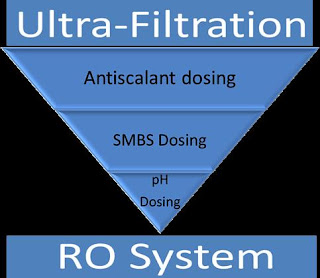

DOSING SYSTEM

In Pharmaceutical Process Water Generation system, Dosing is the process of addition of the external chemical components to

the water as a part of the process water treatment process. This is required to

achieve the aim; to have purified water.

There are three types of dosing system required After Micro

filtration and Before Reverse Osmosis. These are;

|

| Figure:01 Dosing System in Operation Flow of Process water system |

ANTISCALANT DOSING

What

is Antiscalant?

Antiscalant are the chemicals.

This is used in the water treatment before the feed water enters to the process

of Reverse Osmosis. Antiscalant are a family of chemicals designed to prevent

the formation and precipitation of crystallized mineral salts that form

scale.

Calcium Carbonate, Calcium

Sulfate, Strontium sulfate, Barium sulfate is the most responsible mineral

scalants of concern. This scalants are responsible for the causing scaling and

should be targeted.

What is Scale?

This are the mineral components

those deposits on surface, as we are talking about the Process water system

wherein it is used before the Reverse Osmosis (RO) System,

scalants deposits on the RO membrane and impacts on the flow of the water and

reduce the flow rate.

What

is Requirement for usage of Antiscalant?

Antiscalant made of Polyacrylic

acid and are anionic in nature. Sodium hexametaphosphate is being commonly used

as Antiscalant. Antiscalant are

used for preventing the membranes from scaling.

What

is Effectiveness of usage of Antiscalant?

Antiscalant are very

effective in prevention of carbonate and sulphate scaling on membranes, Actually

it does not prevent scaling to occur; rather it delay the formation of large

crystals that form scales.

So that in simple words it

can be said that Antiscalant are being used for the prevention of RO membrane

in the next stage of Water purification, from the damage caused by the various

scalants.

Read also…..

What is Operational Flow of

Pharmaceutical Purified water system?

FAQs on Pharmaceutical

Purified Water system components: what is Multi Grade Filter (MGF)?

FAQs, What is Water

softener? Pharmaceutical Purified Water System components.

FAQs, What is Filtration?

Pharmaceutical Purified Water System components.

SMBS

DOSING

What

is SMBS Dosing?

SMBS dosing is the dosing

of a chemical compound; named Sodium metabisulfate, This is used for the

process of De- chlorination of feed water.

Why

SMBS Dosing is required?

To remove the presence of

chlorine in feed water SMBS Dosing is required. This process helps to avoid

oxidation of RO membranes which is being used in the next stage of Water

purification.

Sodium Hypo-chloride is

used for the Chlorination of water as a part of disinfection process. When

Sodium Hypo-chloride dissolved in the water for dis-infection process of water

it gives free chlorine and water forms Hypo-chlorous Acid (HOCL) with the help

of free chlorine.

Chlorine remains in water

in active form, Active chlorine is corrosive in nature and damage the RO

Membranes. Hence, Removal of this chlorine is required to be removed from

water.

pH

DOSING

For maintenance of pH of

water Caustic Soda i.e. NaOH dosing is used in the water purification process

requirement at this stage is 9 to 10.

What

is purpose of pH Dosing?

CO2 content in water is

considered as an important content & parameter, as CO2 in gaseous form can

pass easily through RO membrane, Hence NaOH dosing is require which transform

CO2 as ion and easily eliminated by RO process.

Learn more……..

- N-Nitrosamine impurities: An Overview

- What are Sartans (A family of Medicine)

- Process Validation study- Types of validation and advantage

- What is Validation study- Basic overview

- Product Lifecycle management- An overview

- Quality Management System- What is Quality Policy